This project was meant to see how much I could improve the looks of an ETA 6498 working exclusively by hand. I started with an undecorated 6498 clone and went through the following steps, which I will detail below:

- Redesign of the bridges’ shapes, rounding most and creating an internal angle

- Straight graining of the flanks

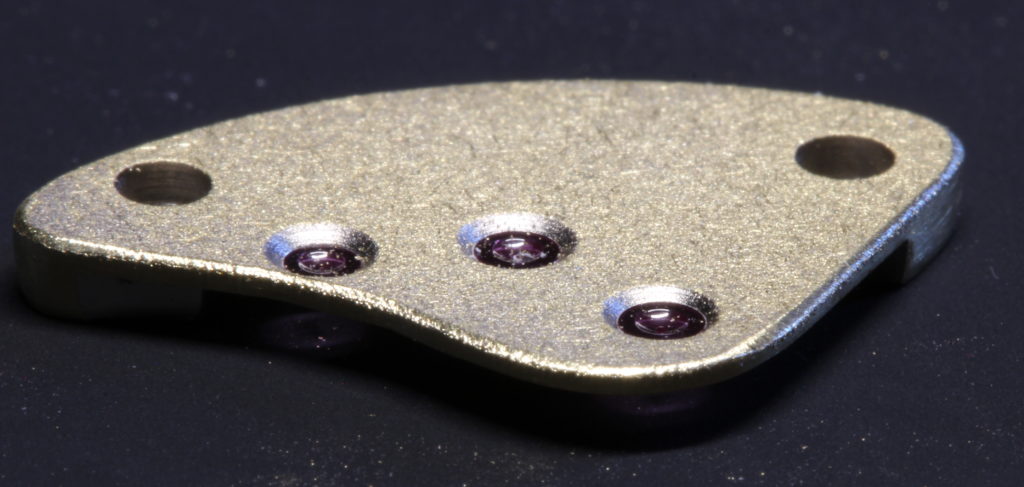

- Frosting of the top of the barrel and train bridges

- Straight graining (satin) of the balance cock

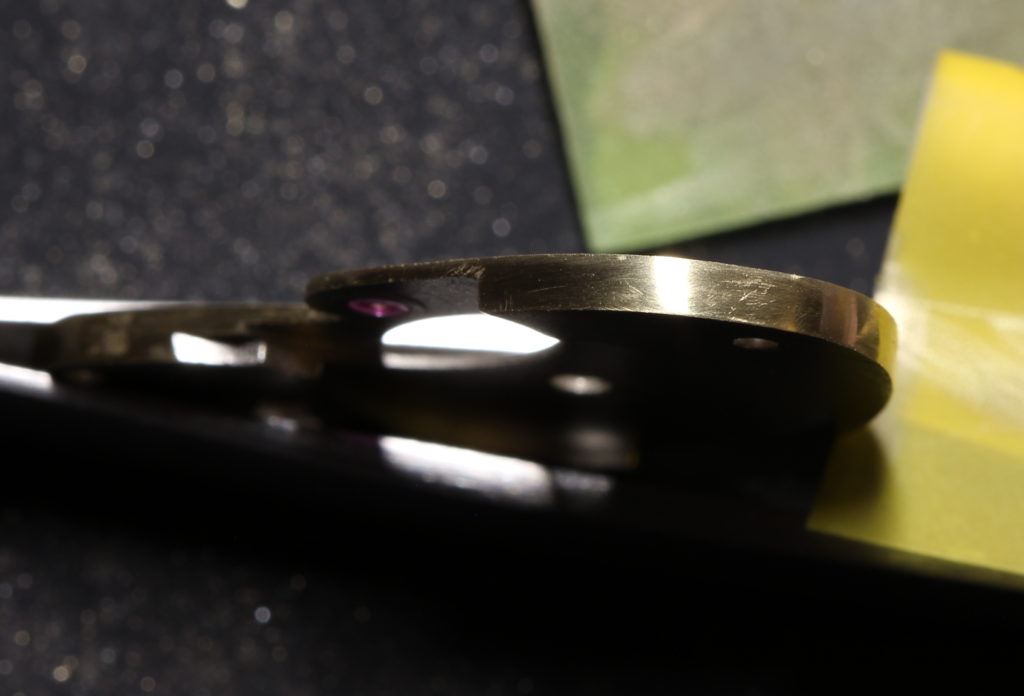

- Beveling of all the bridges

- Polishing of the bevels

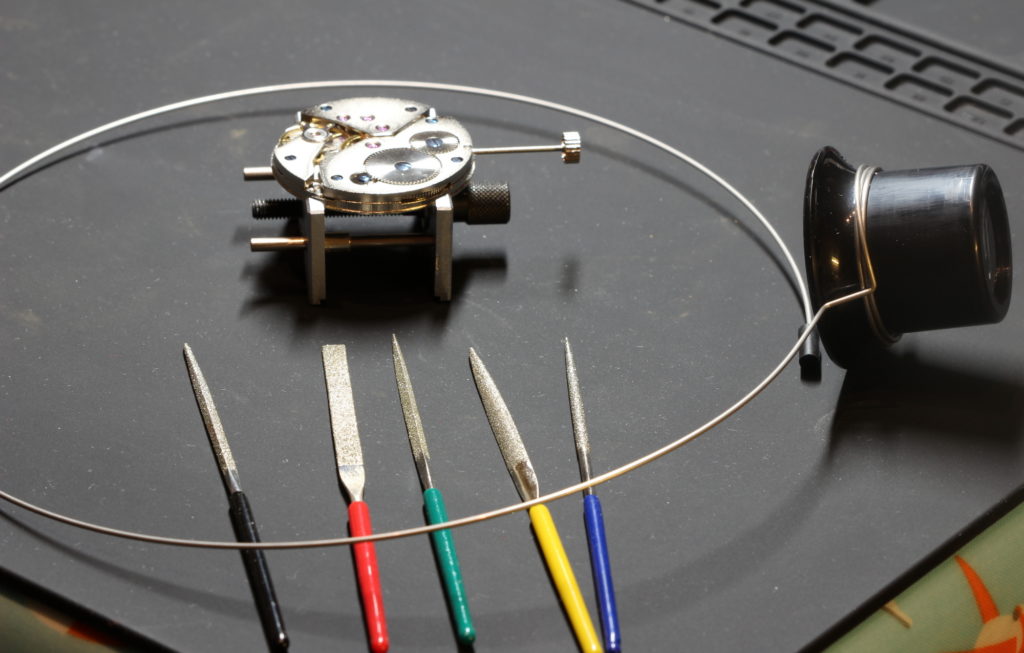

The bridges of the 6498 are extremely angular and not particularly good looking. I therefore decided to smooth most angles except one where I decided to create an internal angle. I did this using 3 small files: one rectangular, one rounded, and one triangular. At this point, I left the corners straight without creating bevels.

To remove the traces of filing and improve the aesthetics, I then used a series of sand papers (grit 240, 600, 1600) on the flanks until they had an almost satin appearance.

I then moved on to the top of the bridges. I decided to give the barrel and train bridges a frosted appearance and the balance cock a satin look. I used an aluminium oxide 80 grit compound mixed in with a few drops of water on a plexiglass surface and rubbed the bridges on it holding them upside down. I used a circular motion to avoid leaving lines.

Once the top surfaces where ready, I used a set of files to create bevels on all top corners. Although I used a different set of files as earlier (because I bought them in the meantime), I used the 3 same shapes: rectangular, rounded, triangular. This set is from Vallorbe and is a cut grade 2 (quite coarse).

The bevels had visible filing marks, which is normal at this point. I then used a series of sand papers to get the surface as smooth as possible. I used both regular sanding paper and lapping paper, but used the latter as sanding paper, not sticking it to anything. Here are the grits I went through:

- 240

- 400

- 1000

- 1600 (12 microns)

- 4500 (5 microns)

- 8000 (3 microns)

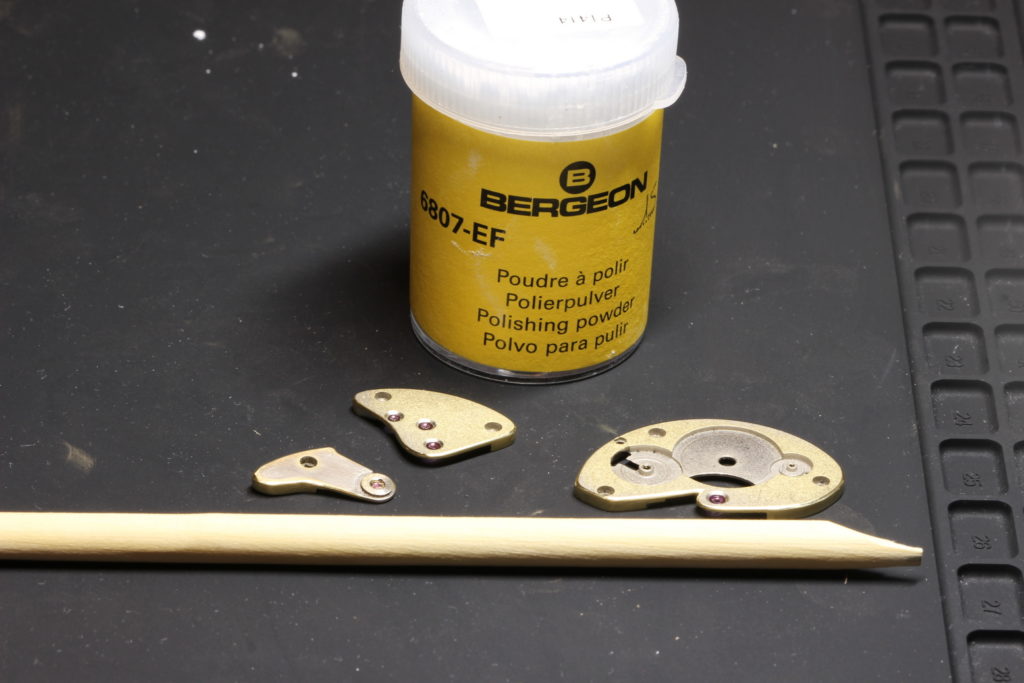

To give a final polish to the surface, I used Bergeon polishing powder on a wooden stick.