This is an ongoing project started in Autumn 2021 and that I am hoping to complete during the summer 2024.

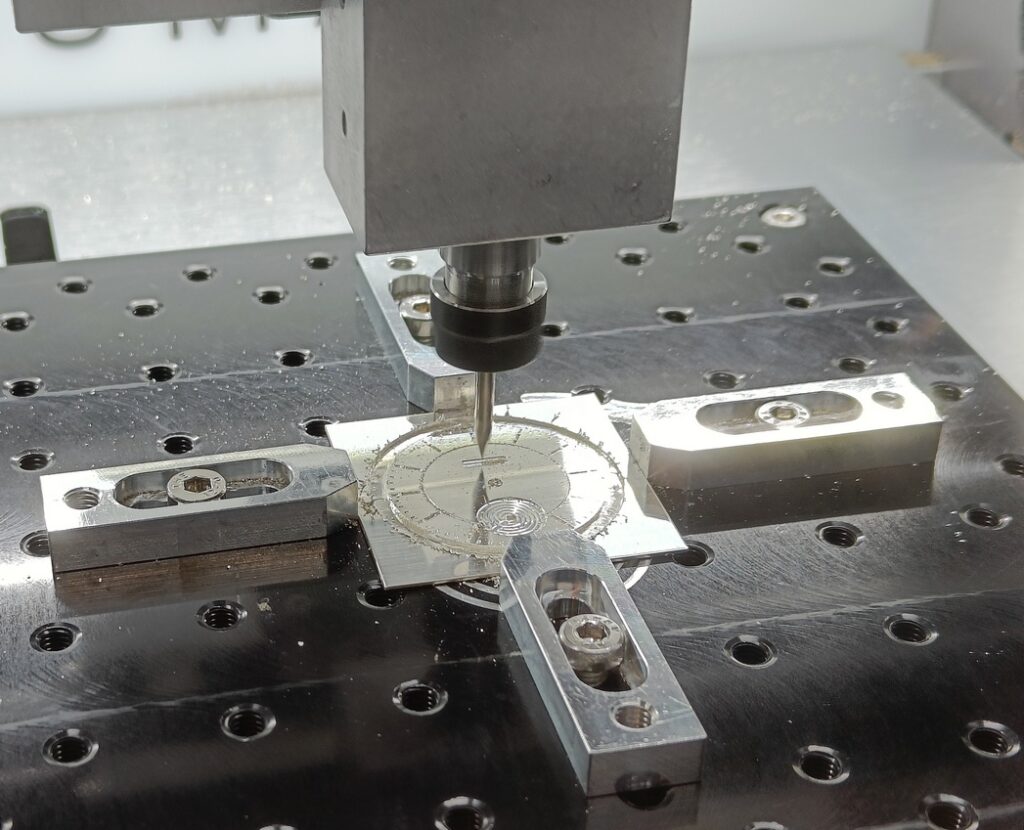

The end product of the first version of the sport watch was of very poor quality because of precision issues. The main change for version 2 is the use of a desktop CNC machine that enabled me to improve precision drastically and to make myself elements that I had previously outsourced.

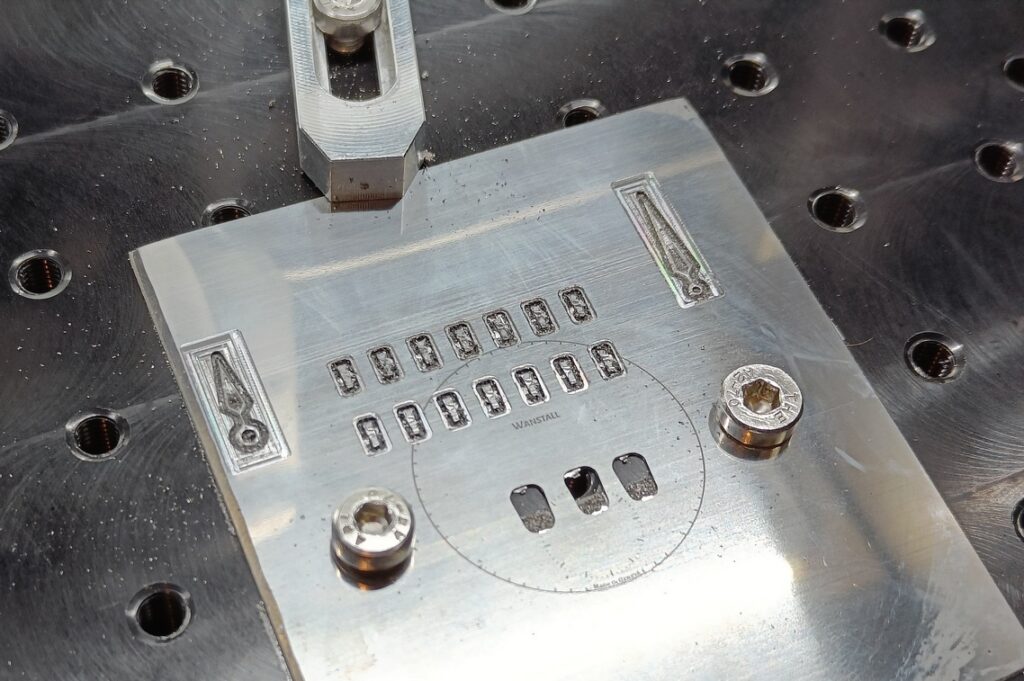

I was able to cut the dial, hands, indices instead of 3D printing them and to engrave the dial instead of having it pad printed.

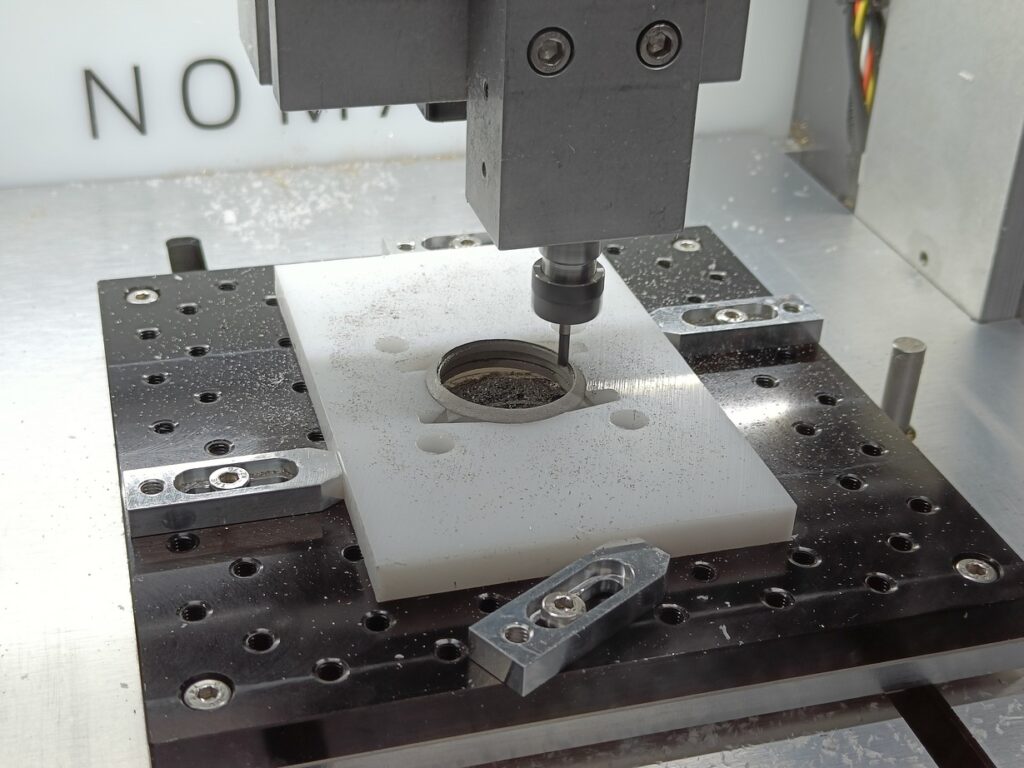

The elements I still had to outsource was the 3D printing of the case and caseback as my CNC is not powerful enough to remove that much hard metal and only works along 3 axes and the buying of crystals, gaskets, and the movement.

For the case, once 3D printed, I used the CNC machine to bring all the elements to the exact dimensions, which allowed for perfect friction fit of crystals.

In terms of design, the changes were small. On the case, I added holes for the straps to allow for fine adjustment.

On the hands, I beveled the sides and created a central hole for the lume instead of a recess.

On the dial, I used engraving combined with engraver’s wax instead of pad printing and the lines are therefore a bit thicker. I changed the logo from a raised signed to an embedded engraved plaque. The plaque is made of brass to create a contrast with the silver of the rest of the dial.