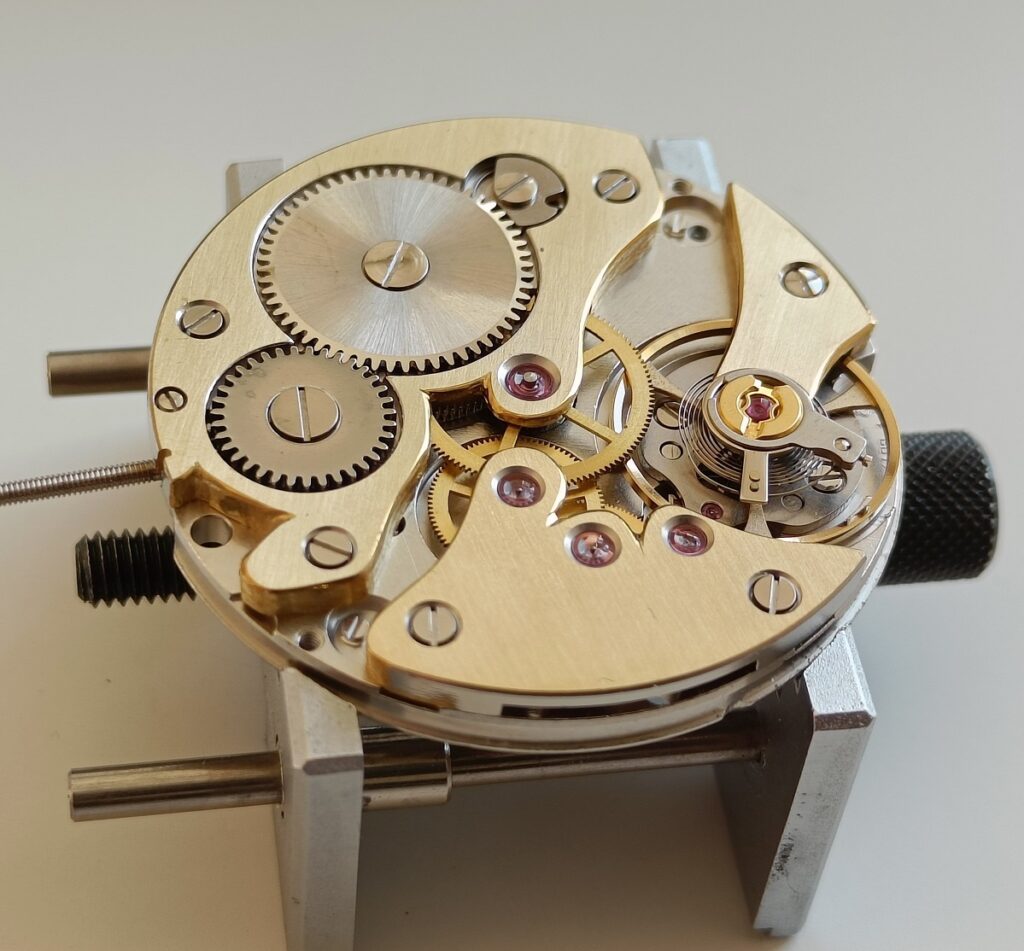

I bought an ETA 6498 movement as it is simple and readily available and I prefer hand-wound movements aesthetically. There are therefore only a few things I wanted to do:

- re-shape the bridges

- re-finish the top of the bridges

- bevel the edges

- polish the bevels

- clean, service and re-assemble the movement

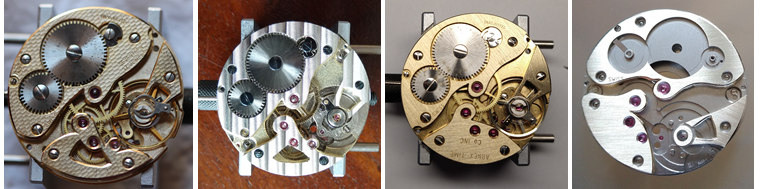

For version 1 of the sport watch, I went through different versions of the bridges and decided finally on shapes and finishing techniques that were less complex.

The bridges were re-shaped using a fine metal hand saw, then a rotary tool (with cutting and abrasive wheels and drills) and then hand files and abrasive paper. The bevels were then created with hand files and then polished with a series of finer and finer abrasive papers (7 grits from 400 to 8000).

(with 400 grit paper)

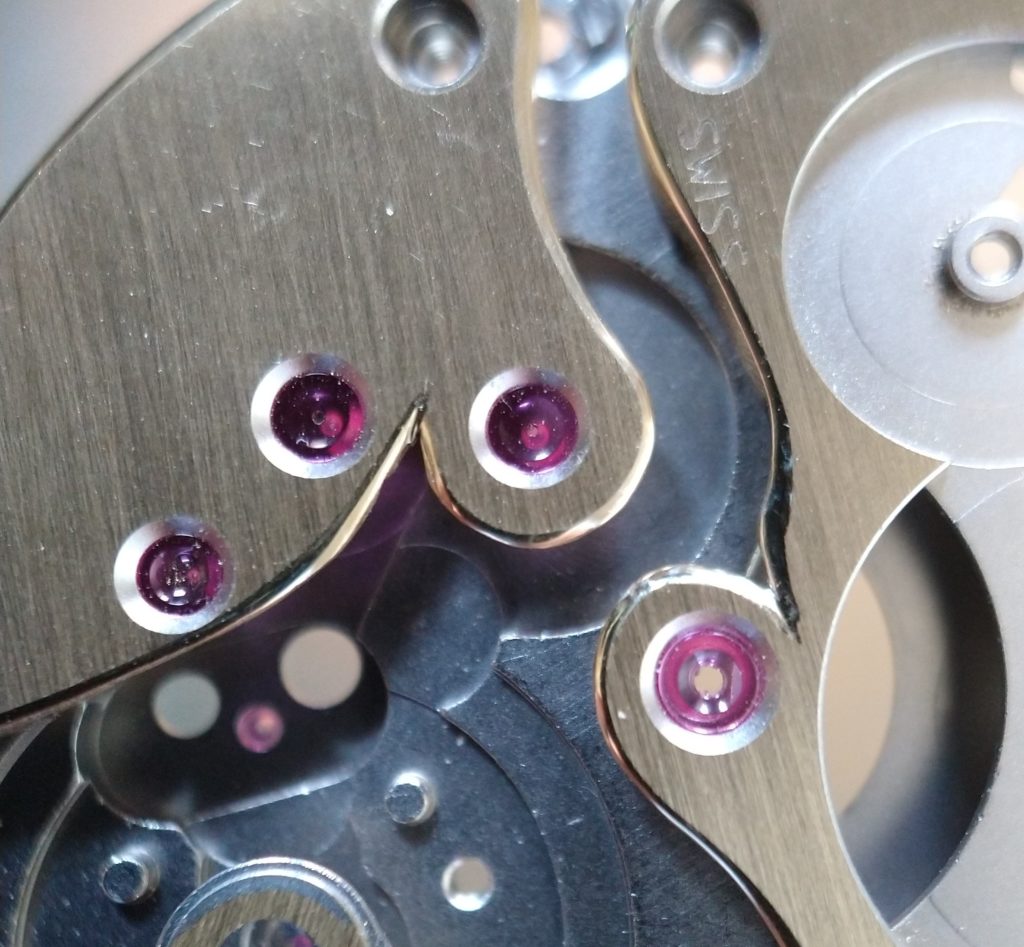

The last step in the process was to clean the parts with an ultrasonic cleaner and then reassemble the movements while oiling the rubies. Once re-assembled, the movement had to be regulated with a timegrapher.

For the second version of the sport watch project, I simplified the design of the balance cock as the hole in the middle was very difficult to bevel and polish.