Frosting or graining is the surface finishing that can be seen on many old English watches and has now made a comeback in high-end watches. For me, it’s great advantage is that it does not require specialized machinery.

A good overview of frosting techniques can be found in this article by WatchesbySJX.

Frosting creates a rough surface that is not too reflective and therefore offers a perfect contrast to polished bezels. It can be achieved by at least 3 techniques: sanding (blasting sand on the part with a special machine), with a texturing wheel (only requires a hand-held rotating tool), or with abrasive pastes.

I started by using abrasive pastes as this required the least investment and I liked the idea of creating something without any machinery. I used abrasive pastes, either aluminium oxide (AO) or silicon carbide (SC), on a piece of plexiglass and pressed the piece against it upside down while making circular motions. I found I had more striking results with AO grit 80 than with SC grit 120. However, in both cases I was unable to avoid scratches and it was especially difficult to apply this technique on a part with recesses as the paste would build up in the recesses in the part.

Then, upon recommendation from Christian Lass from learnwatchmaking.com, I tried with loose silicon carbide beads and replaced the plexiglass (too soft) with glass. I used alcohol to create a paste-like texture.

I was also careful to use very small gestures to decrease the risk of scratches.

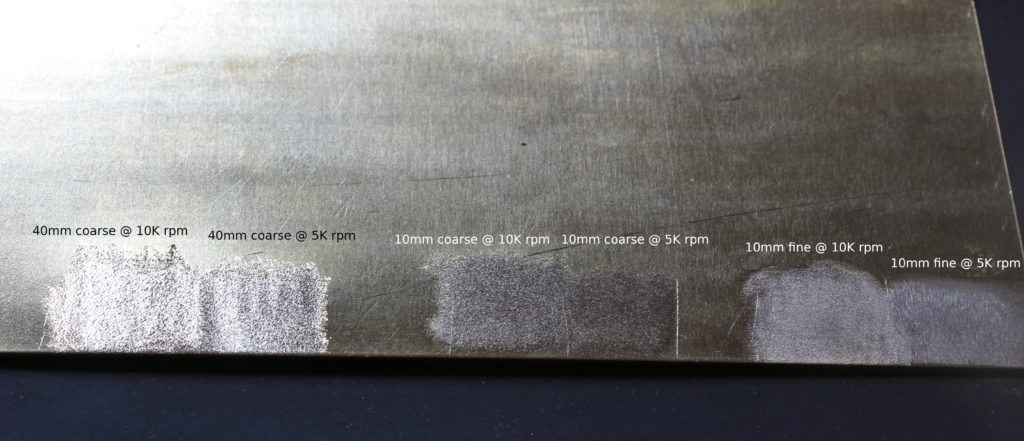

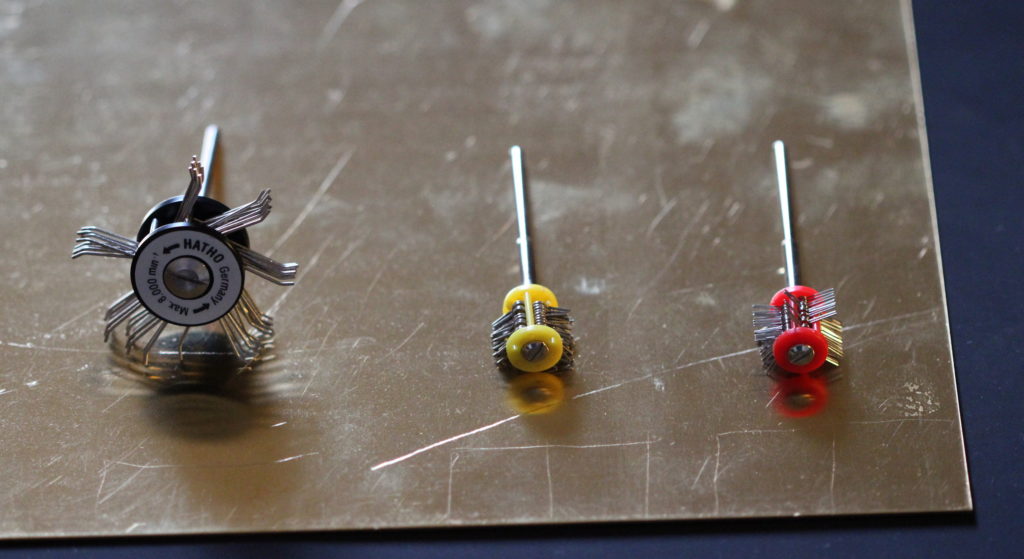

I then moved to texturing wheels and have tried several sizes and levels of coarseness. Small wheels 10mm combined with fine strands gave a satin result where the lines were visible. It was easier to get a uniform surface with coarser wheels, even with a small diameter. However, to have a more dramatic effect, larger wheels (40mm) are better.

I also found that for smaller wheels a higher number of revolutions per minute (rpm) made it easier to have a uniform surface with no visible lines. Therefore for 10mm wheels I recommend 10’000 rpm, whereas with larger wheels (40mm) 5’000 rpm seems better.