In October 2019 I started to work on the design and production of a watch, which I completed in April 2021, having worked on it roughly 300 hours. I have listed in the table below what I have done myself, what I have outsourced because I did not have the tools required, and the components that I bought. I ended up buying the movement, crystals and gaskets and either doing the rest myself or having my designs printed professionally. I believe this makes this watch comparable to any watch from a watch company that does not produce in-house movements.

What I did

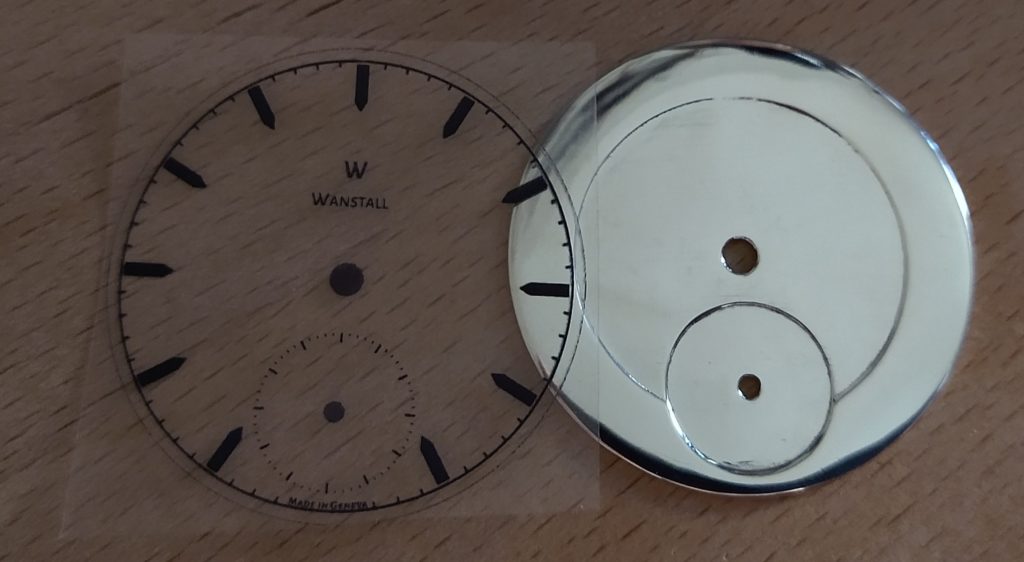

- Design the base dial

- Texture the base dial

- Design the printing on the dial

- Design the indices

- Finish the indices

- Design the logo

- Finish the logo

- Assemble all components of the dial

- Design the case

- Finish the case

- Re-finish the movement

- Service the movement

- Assemble the movement, dial and encase them

What I outsourced

- 3D printing the dial

- Pad printing on the dial

- 3D printing the indices

- 3D printing the hands

- 3D printing the case, caseback and crown

What I bought

- ETA 6498 movement

- Screws, gaskets and glasses

The number of steps in the process of creating the watch are quite large and I realized early on that I would need a system to organise the work on the different components, manage dependencies and track my progress. I chose to use a Gantt chart and the online TeamGantt website, but any Gantt chart software or even spreadsheet would work.

I used free software to design the vector graphics (BoxySVG) and 3D models (FreeCAD). I also used Blender to create 3D images.